Water Quality Improvement Device

ARIORES is a patent product with over 40 years of research and development.

It prevents and removes the scale which adhered and suppresses the occurrence of red rust without damaging the piping used in all materials and applications.

ARIORES contribute to environmental protection with products that are friendly to people and the environment that do not use any chemicals.

※ Scale: Calcium and so forth dissolved in water stuck inside the pipe

The efficiency and advantages of electromagnet

- Prevention and removal of scale, silica and rust (red water) in piping

- Maintenance and prolongation of service and water supply and drainage, cold and hot water, cooling water, piping of piping equipment and related equipment (prevention of deterioration)

- Removal of sticking dust on the heating surface of the boiler, saving of labor and maintenance

- Control of outbreak of general bacteria, legionella genus bacteria

- Preventing and cleaning up rust,dregs,silica into water pipe changing red rust which pipe was leaked out by the red rust to black Rust that the black rust will extend the expiration.

- It will extend extend the expiration.

Cleaning up and protecting stain of the cooling system, lubrication tools, then it will react from a sharp crystal to a hexagonaL crystal, that it cannot be in a pipe. - It will help you to save power of device, easy to look after, reduce cost of utilities and cost of fixing or changing a pipe, so the cost of utilities will be 300-900 per year

- It will help you to reduce Bacteria preserving environment, we have never used chemicals and our employees will never touch with chemicals

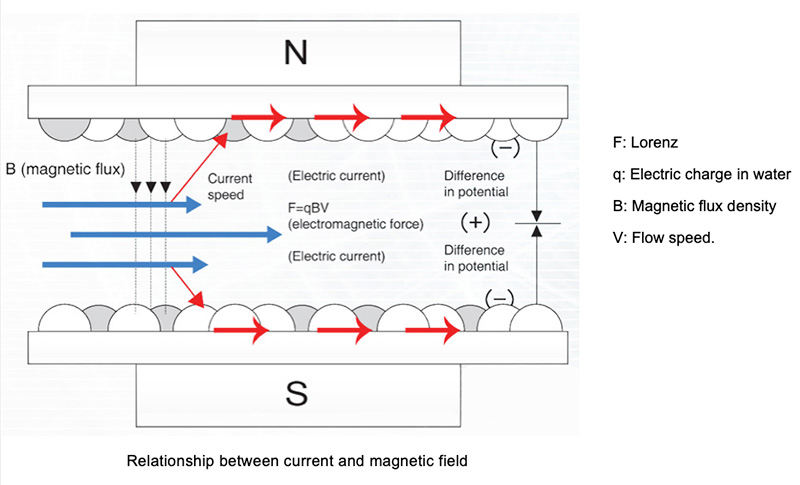

Magnetic Field

When N, S magnets are attached to the outside of the pipe, current induced by Faraday's law of induction flows along the tube wall.

Removal of scale by installing the magnetic field part and electric field part within the pipe, a line of magnetic force is generated within the pipe. When fluid passes through this line of magnetic force, an electric current is generated along the pipe wall, which causes electrolysis. Due to this electrolysis, the substances adhered to inner walls of piping, such as scale are gradually removed/dissolved. (Faraday’s law of electromagnetic induction) Scale adhesion not only shorten the lifetime of piping but also reduces heat exchanging effect of heat exchanger/condensation machine etc., which will result in energy loss. Additionally, it will be the major cause that may incur enormous costs for pipe washing work or renewal work.

Red oxide (Rust) is found in oxygen rich environment, where the iron, oxygen and the presence of water mixed to form a chemical reaction. ARIORES reduces red oxide and eventually formed a black oxide which is a good protection for metal.

ARIORES also reduces the formation of bacteria like legionella as it removes scale and slime which is a hot bed for bacteria growth.

Overall, ARIORES helps to reduce maintenance cost and also contributes to environmental protection by reducing and eventually eliminating the use of chemical.

Installation of ARIORES

Schools

Incinerators

Distribution Centres

Cruise Ships

Hotels

Cooling Water

Well Water

Boiler Water Pipes

Intermediate Water

Water Heating and Cooling

Factories

Newly Built Condominiums

Schools

Large-scale Public Baths

Hopitals

Industrial Water

Water Suply

Cooling Piping System

Recycled Water

Hot-water Supply

Effects of ARIORES

Dissolving and Pealing of Scales

Before

A water pipe on which have developed

After

95 days after using ARIORES device

The 3 Major Effects of ARIORES

1. Scale, Silica

Paper Factory (scales in production line pipes)

Line WITHOUT ARIORIES installed

These pipes were maintained by removing them every 4 months and removing scales with high pressure washing.

VS

Line WITH ARIORIES installed

Fewer scales attached themselves after installing Ariores, and the frequency and cost of subsequent maintenance were drastically reduced as a result.

Office building (Scales inside cooling tower)

Line WITHOUT ARIORIES installed

The cooling tower was maintained by using chemicals and regular cleaning at an enormous expense because silica scales would affix themselves.

VS

Line WITH ARIORIES installed

A great cost cutting effect was achieved by maintaining the tower without the use of chemicals and installing Ariores.

2. Rust

Building materials factory (Red rust inside compressor aftercooler)

Before installing ARIORIES

To clean this after -cooler, a very long removal process was required that involved manual labour and the use of chemicals.

Nine months After installing ARIORIES

Red rust and scales peeled off after installing ARIORES, and further development of rust and scales was prevented.

The cooler returned to a normal state and maintenance was successfully made easier and cost effective.

3. Bacteria

Bathing facilities Test date : December 20, 2001 (Legionnaire's bacteria in bathtubs)

Examination BEFORE installation of ARIORES

- Test date : December 20,2001

- Water in hot water tank : 10CFU/less than 100ml met standards

- Boy's bath : 740CFU/100ml failed standards

- Girl's bath 600 CFU/100ml failed standards

Before installing ARIORES

The germs/legionnaire's bacteria in the circulating baths were managed by pouring sodium into the water, but since the sodium does not reach the biological slime in the pipes, legionnaire’s bacteria can be found depending on the density of the sodium.

Examination AFTER installation of ARIORES

- January 5,2002 (Ariores installed)

Ariores A model 80A, 2 machines - February 14, 2002 (examination after installing Ariores)

- Water in hot water tank : 10CFU/less than 100ml

- Boy's bath : 10CFU/100ml met standards

- Girl's bath : 10CFU/100ml met standards

Effects 40 days after installing ARIORES

Biological slime peeled off along with scales after installing Ariores, and we verified many test results showing an extreme drop in the concentration of germs.

Water supply facilities

(Regular germs and bacteria found in water used at schools and wells)

Examination BEFORE installation of ARIORES

- Test date : September 1,2003

2nd floor water faucet : 150,000 parts per ml

Before installing ARIORES

The well water is treated with sodium, but when school is out of session, the water becomes stagnant, the sodium disappears, and germs formed in large quantities, producing an intense smell.

Examination AFTER installation of ARIORES

- September 1, 2003 (Ariores installed)

Ariores L model, 100A, 1 machine - December 12, 2003 (examination)

2nd floor water faucet : 0 parts per ml

Effects 3 months after installing ARIORES

After taking a water quality test under the same conditions (the Monday after a 2-day weekend), we did not find any regular germs 4 months after installing ARIORES, and the smell had lessened.

Example of ARIORES Construction

Pipes with Heating or Racking

(Hotels / Water Supply Pipes / Installation of ARIORES L Model 100A)

Tower part

Mounting ARIORES after removing racking/ heat insulation

Restoringracking/ heat insulation

Steel Pipes

(Supermarkets / Cooling Pipes / Installation of ARIORES L Model 200A)

Before mounting Piping condition

Mounting state of ARIORES

Vinyl Chloride Pipe (Bathing Facilities / Circulation Piping)

Mounting ARIORES by winding steel plate around vinyl chloride pipe

SUS Piping

(Factory/Solution Pipeline)

Mounting ARIORES by coating steel plate around SUS piping

Buried Pipe (Elderly Nursing Home/ Water Distributing Pipe for Well)

Mounting the magnetic field part of ARIORES and burying with anticorrosive treatment

Mounting Outdoors

The magnetic field part of ARIORES is mounted being stored in a case

SOLUTIONS FOR TOUGH BEARING PROBLEMS

What is self-lubricating GRAPHALLOY?

What can it do for you?

GRAPHALLOY, a graphite/metal alloy, is formed from molten metal, graphite and carbon; it is a uniform, solid, self-lubricating, bushing and bearing material. From this material we manufacture a unique, self-lubricating bearing solution, offering superior performance in hundreds of applications. GRAPHALLOY material is suited for submerged or high temperature bearings or bushings - applications where oil, grease and plastics fail.

Available in over 100 grades, GRAPHALLOY bearings may be the solution to your toughest bearing, bushing, thrust washer, cam follower, or pillow block bearing design problem. Some GRAPHALLOY bearings have operated for up to 20 years without maintenance. We have many standard designs but most of our products are custom designed to the unique requirements of your specific application.

To find out more about our products email us.

GRAPHALLOY products are used in virtually every manufacturing industry:

- Pumps: Vertical and Horizontal

- Bushings for Submerged Applications

- Food Applications requiring FDA acceptance

- High Temperature

- Low Temperatures

- High Speeds

- High Loads

- Current Carrying Applications

- Vacuums

- Custom Designed

The GRAPHALLOY® Advantage

GRAPHALLOY®, a graphite/metal alloy, is a unique self-lubricating bearing material that offers superior performance in hundreds of mechanical and electrical applications.

GRAPHALLOY standard and custom designed products provide lifetime cost savings and significant operating advantages over conventional bushings and bearings.

| Features | Benefits |

| Self-Lubricating | Requires no grease or oil. Permits continuous operation and eliminates downtime. |

| Hot | Works at high temperatures where oil-based lubricants burn off or oxidize and plastics fail. Operating temperatures to 1,500º F / 800º C (in non-oxidizing atmospheres). Will not gum or seize. |

| Cold | Does not congeal or solidify at low temperatures or cryogenic conditions. Maintains self-lubrication. |

| Dry | Works without lubrication. Survives run dry applications. Eliminates galling or seizing in hot and dry conditions. Will not attract dust. |

| Wet | Operates submerged. Will not swell or wash out. Withstands a wide variety of hostile fluids. |

| Dimensionally stable | Does not cold flow or deform under pressure. Maintains its size and shape. |

| Chemically Resistant | Insoluble in most industrial liquids. Works in acids, alkalies, hydrocarbons, water, and liquid gases. |

| Low Coefficient of Friction | Constant, low coefficient of friction. Not just a surface layer, solid throughout. |

| Linear Motion | Maintains lubrication during linear motion. Lubrication is not drawn out and dust is not pulled in. |

| Current Conducting | Eliminates sparks and static. Conducts well. |

| FDA Accepted | Accepted for food services. No lubrication to drip or cleanup. Easily steam cleaned. |

We supply genuine OEM parts from various manufacturers.

Please call to enquire.

| Item No. |  VP215 VP215 |

|

| Frequency | 50Hz | 60Hz |

| Flow Rate | 1.5CFM | 1.8CFM |

| 42L/MIN | 50L/MIN | |

| Ultimate Vacuum | 3×10-1 | Pa |

| 25microns | ||

| Power | 1/4HP | |

| Inlet Port | 1/4"Flare | |

| Oil Capacity | 180ml | |

| Dimensions | 270mm×119mm×216mm | |

| Weight | 6KG | |

| Item No. |  VP225 VP225 |

|

| Frequency | 50Hz | 60Hz |

| Flow Rate | 2.5CFM | 3CFM |

| 42L/MIN | 50L/MIN | |

| Ultimate Vacuum | 3×10-1 | Pa |

| 25microns | ||

| Power | 1/3HP | |

| Inlet Port | 1/4"Flare | |

| Oil Capacity | 280ml | |

| Dimensions | 278mm×119mm×216mm | |

| Weight | 7KG | |

| Item No. |  VP235 VP235 |

|

| Frequency | 50Hz | 60Hz |

| Flow Rate | 3.5CFM | 4CFM |

| 100L/MIN | 114L/MIN | |

| Ultimate Vacuum | 3×10-1 | Pa |

| 25microns | ||

| Power | 1/3HP | |

| Inlet Port | 1/4"Flare&3/8"Flare | |

| Oil Capacity | 360ml | |

| Dimensions | 320mm×134mm×232mm | |

| Weight | 11KG | |

| Item No. |  VP245 VP245 |

|

| Frequency | 50Hz | 60Hz |

| Flow Rate | 4.5CFM | 5CFM |

| 128L/MIN | 142L/MIN | |

| Ultimate Vacuum | 3×10-1 | Pa |

| 25microns | ||

| Power | 1/2HP | |

| Inlet Port | 1/4"Flare&3/8"Flare | |

| Oil Capacity | 350ml | |

| Dimensions | 320mm×134mm×232mm | |

| Weight | 11.8KG | |

| Item No. |  VP260 VP260 |

|

| Frequency | 50Hz | 60Hz |

| Flow Rate | 6CFM | 7CFM |

| 170L/MIN | 198L/MIN | |

| Ultimate Vacuum | 3×10-1 | Pa |

| 25microns | ||

| Power | 3/4HP | |

| Inlet Port | 1/4"Flare&3/8"Flare | |

| Oil Capacity | 700ml | |

| Dimensions | 370mm×140mm×252mm | |

| Weight | 15KG | |

| Item No. |  VP280 VP280 |

|

| Frequency | 50Hz | 60Hz |

| Flow Rate | 8CFM | 9CFM |

| 226L/MIN | 254L/MIN | |

| Ultimate Vacuum | 3×10-1 | Pa |

| 25microns | ||

| Power | 1HP | |

| Inlet Port | 1/4"Flare&3/8"Flare | |

| Oil Capacity | 600ml | |

| Dimensions | 370mm×140mm×252mm | |

| Weight | 15.5KG | |

| Item No. |  VP2100 VP2100 |

|

| Frequency | 50Hz | 60Hz |

| Flow Rate | 10CFM | 12CFM |

| 283L/MIN | 340L/MIN | |

| Ultimate Vacuum | 3×10-1 | Pa |

| 25microns | ||

| Power | 1HP | |

| Inlet Port | 1/4"Flare&3/8"Flare | |

| Oil Capacity | 600ml | |

| Dimensions | 390mm×140mm×252mm | |

| Weight | 16KG | |

- Reconditioned Machines

- Vacuum pump

- Tube cleaning machine

- Recovery unit

- We sell refrigerant like R22, R134a, R123 and others.

- We also sell recycled refrigerants.